The sound insulation principle of acoustic louvers is mainly realized through sound deadening and sound absorption. Specifically:

1、Muffling principle: soundproof louvers are composed of a series of louvers, which are connected with springs between the blades to form a kind of muffler. When the sound enters the muffler louvers, it will produce friction and interference between the blades, thus reducing the intensity of the noise.

2、Sound-absorbing principle: At the same time, the gap between the blades can also play a role in sound absorption, further reducing noise. In addition, soundproof louvers also have the advantages of simple structure, easy installation, remarkable noise reduction effect, long service life and wide range of application. In the industrial noise reduction project, soundproof louvers can be widely used in a variety of mechanical equipment produced by the reduction of Pinji, such as machine tools, stamping equipment, engines, exhaust systems and so on.

PRODUCTS

Tel:+8613027778101

E-mail:bonnie@yh-acoustics.com

Product details description

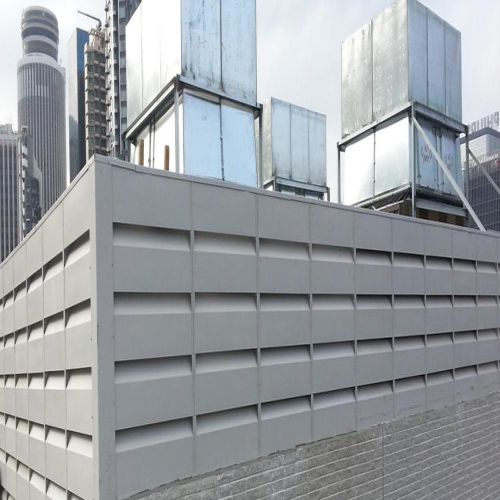

Acoustic barriers are mainly used outdoors, and are designed to block the direct sound between the sound source and the receiver by inserting a facility between the sound source and the receiver, so that there is a significant additional attenuation of the sound wave propagation, thus attenuating the noise impact in a certain area where the receiver is located. YH-acoustics™ noise barriers are composite noise barriers that combine sound absorption with sound insulation.The combination of louvered panels and sound-absorbing cotton greatly improves sound insulation effect.

Specifications

Thickness: Varies

Material: Perforated Galvanised Steel, Steel Sheet and Rockwool

Accessories: Channels, flashings and doors

Panel finish: Corrosion resistant coating

Bird mesh: Yes

Weatherproof: Yes

Color:grey,white,other colors available on request

Typical Applications

•Acoustic enclosures for air-conditioning intake

•Acoustic enclosures for generators

•Complete stand-alone acoustic plant rooms

•Central ventilation systems

•Workshop ventilation

•Cooling towers

•Wall grilles

•Acoustic ventilation screens