The main structure of the acoustic enclosure is the enclosure wall, modular acoustic panels are one of the most commonly used enclosure walls. When the enclosure wall has enough sound insulation, it can block the noise of the sound source machinery and equipment from going out, so that the noise can be reduced to below the stipulated permissible sound level. Acoustic enclosures are usually categorized into fully enclosed enclosures, movable enclosures, and partially enclosed enclosures.

PRODUCTS

Tel:+8613027778101

E-mail:bonnie@yh-acoustics.com

Product details description

Introduction

The acoustic enclosure is designed according to acoustic principles, mainly in fully closed mode (can be used in combination with acoustic doors, observation windows, ventilating and silencing louvers, air intake and exhaust silencers, etc.) to effectively block the outward transmission and diffusion of noise, and the acoustic isolation effect can be up to 20~40dB.

Acoustic enclosure shell by a layer of impermeable metal materials with a certain weight and rigidity, generally 2 ~ 3mm thick steel plate, the internal light steel skeleton supplemented by damping materials, sound-absorbing / sound-insulating materials, dust-proof materials to microporous acoustic resonance body as the main structure. With high efficiency sound absorption, sound insulation, vibration isolation, beautiful modeling, fire, rain and other characteristics. It can effectively control and isolate the spread of noise radiation to the outside.

Features

1, soundproof enclosure internal sound absorption, external sound insulation, both for indoor and outdoor

2、Visualization with the installation of soundproof doors and windows.

3、Waterproof, moisture-proof, fire-proof, UV-proof

4、Pre-fabricated panels for easy transportation, installation and maintenance.

5、Color, size, thickness and filling can be customized .

Sound reduction

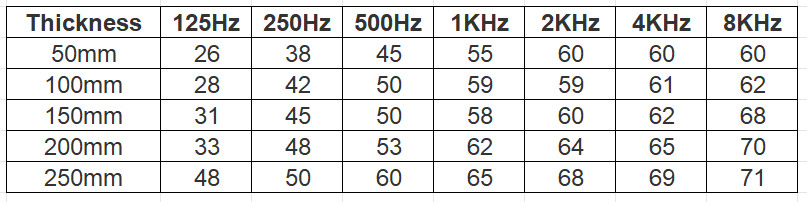

Insertion loss of acoustic enclosure in 25-70dB (A)

Applications

Widely used in large fans, generator sets, glass tempering furnaces, punching machines, milling machines, air compressors, fans, pumps, blowers, induced draught fans, generators, transformers, pulverizers, ball mills, electric motors, woodworking machinery, air-conditioning outdoor units and so on;